Add to Cart

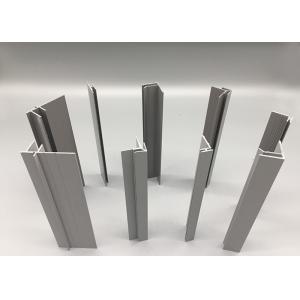

Shinning Painted Powder Coated Aluminum Extrusions Oxidation Resistance

Product Description:

Aluminum Extrusion parts with high quality

1. Material: Aluminium alloy 6063, 6061

2. Temper: T4,T5, T6

3. Quality standard: GB5237-2008

4. Surface treatment: Mill finish, anodized, powder coated, electrophoresis, sand balsting,polishing, etc.

5. Color avalilable: Silver, champagne and so on, Depends on your design

6. Packing details: Plastic Bag, Carton, Plywood Box or as customized

7. Samples: 10~15 working days after receive the mold fee

8. Delivery: 15~25 working days after deposit

9. Production Capacity: 5000MT/Month

10. MOQ: 5 TONS

12. Payment terms: T/T, Paypal,West Union

13. Port: Wuhu/Nanjing/Shanghai

We can provide fabrication,deep drawing,machining,welding and assembly.

A variety surface treatments are available: polishing, zinc plating, nicke plating, chrome plating, powder coating,e-coating,dip coating,phosphate coating and so on.

If you have any needs for those products,please don't hesitate to contact us . We will provide our best price for you once get your kind enquiry.

Please let us know the specifications, quantity and packing you want, we will reply you ASAP.

1)Chemical composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | AI |

| 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | 0.1 | 0.15 | REST |

| 6061 | 0.2-0.6 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.15 | REST |

| 6005 | 0.6-0.9 | 0.35 | 0.1 | 0.1 | 0.4-0.6 | 0.1 | 0.1 | 0.1 | 0.15 | REST |

2)Mechanical property

Alloy | Temper | Tensile strength | Yield strength | Elongation |

| 6061 | T6 | ≥ 265Mpa | ≥ 245Mpa | ≥ 8% |

| 6063 | T5 | ≥ 160Mpa | ≥ 110Mpa | ≥ 8% |

| T6 | ≥ 205Mpa | ≥ 180Mpa | ≥ 8% |

3)Anodized

Grade | Anodizing thickness | Hole scaling quality of oxide layer | |

| Average thickness | Local thickness | P. Cr acid-erosion weight less method | |

| AA10 | ≥10um | ≥8um | ≤30 mg/d m2 |

| AA15 | ≥15um | ≥12um | |

4)Powder coating & wooden-grained

Coating thickness | Coating impress rigidity | Adhesive force of coating layer |

| 40-120um | Indentation hardness>80 | 0 grade |

Production Line:

12 extrusion machine

4 anodize line

3 powder coating line

2 wood color line

1 polish line

Overseas Market:

Asia: India,Philippines,Vietnam,Thailand,Malaysia,Singapore,Palestine

Europe:Italy, Germany, Finland,United State,Ukraine,Cyprus

America:Mexico,Brasil,Colombia,Venezuela,Argentina

Africa:Algeria,Egypt,Libya,Ethiopia,Senegal,Nigeria,South Africa

Surface Treatment we could offer:

Mill Finish, Anodize,Powder Coating,Electrophoresis,Polish,Wood Color,Thermal Break