Add to Cart

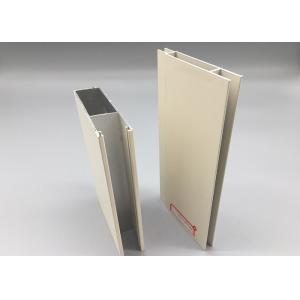

Professional T3 Powder Coated Aluminum Extrusions , Standard Extrusion Profiles

| Surface Treatment: | mill finish,powder coating,anodize,polish,electrophoresis,wood color |

| Film Thickness: | 8-10um for anodize(Max 25um), 40-120 for powder coating |

| Color: | Specified by customer according to international RAL color brand |

| Alloy Temper: | 6063/6061 T4,T5,T6 |

| Hardness: | Min HW9 |

| Mold Cost: | USD300 each and refund once quantity up to 5 tons each |

| Mold making time: | 10-15 days |

| Packing: | Plastic protective film+heat shrinking bag, or with pearl wool, as to client's require. |

| Delivery Time: | 20 day for 3*40HQ |

| Payment: | TT/LC |

| Standard: | GB/T 5237 |

| Capacity: | 50,000 ton pear year |

Production Line:

12 extrusion machine

4 anodize line

3 powder coating line

2 wood color line

1 polish line

Overseas Market:

Asia: India,Philippines,Vietnam,Thailand,Malaysia,Singapore,Palestine

Europe:Italy, Germany, Finland,United State,Ukraine,Cyprus

America:Mexico,Brasil,Colombia,Venezuela,Argentina

Africa:Algeria,Egypt,Libya,Ethiopia,Senegal,Nigeria,South Africa

Surface Treatment we could offer:

Mill Finish, Anodize,Powder Coating,Electrophoresis,Polish,Wood Color,Thermal Break

Our Advantage

1.Our manufactory have all kinds of the equipments such as blast furnace,extrusion line,Temper machine, horizontal powder coating line, new Anodize machine,cuting and drilling manchine and so on."

2. We have 60 Quality Control Engineers and their assistants, and we also have a lot of testing equipment. such as: a materila testing lab,Coating Thickness Gauge and so on.We will inspect each of our product carefully before the shipment.

3.The delivery time and the package can be controled according to the customers' requirement completely.

4. Strict quality assurance and inspection measures will never let any imperfect products be out of our company.

5. We can provide the best service and the competitive price for you.

Our characteristic service

1.OEM Service

2.Our 15 engineers can design the products according to the customers' requirement completely.

3.After 10 years of experience in manufacturing, we have had many kinds of the moulds ourselves. So we can save the mould fee and delivery time for the customers for some kinds of the products.